Technological Innovations in the Industrial Grinder Industry

Smart Automation

The integration of smart automation in industrial grinders allows for precise control and optimization of the shredding process. This not only enhances efficiency but also reduces energy consumption and waste.

Advanced Material Sorting

Industrial grinders equipped with advanced material sorting technologies, like metal detection and metal separation, can separate different types of materials during the shredding process. This not only improves recycling efficiency but also enables the recovery of valuable resources from waste streams.

Modular Design

A modular design approach facilitates easy upgrades and maintenance, extending the lifespan of the equipment. This reduces the need for frequent replacements and minimizes the environmental impact associated with manufacturing new machinery.

Industrial grinders and shredders, in particular, are exposed to very brutal operating conditions on a daily basis. One of the most insightful truths I’ve heard in my years of serving Cresswood Shredding Machinery is that ALL grinders work well when they are first put into service, but it is how they still perform 5, 10, or more years after where the differences are exposed. Another valuable truth I’ve heard is that in the game of Industrial grinders, it is the heaviest build that always wins in the long term. This speaks volumes about how engineering and design play such a critical role in limiting the cost of ownership over time. This truth also tips its cap to the first in that out of the gate all these systems will perform satisfactorily, but the differences eventually manifest themselves over time as the rigors of what they are tasked to do inevitably take their toll.

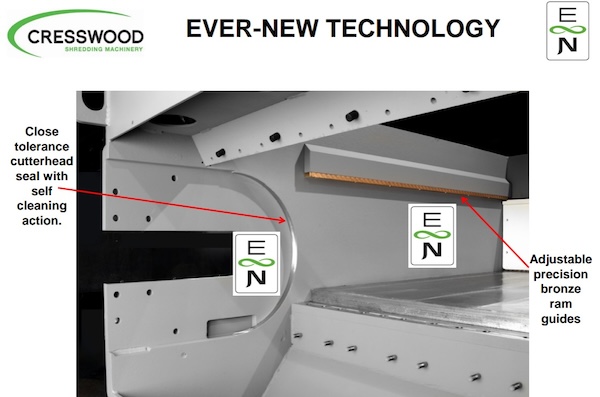

Cresswood’s EVER-NEW Technology is Innovating Durability

At Cresswood Shredding Machinery, we embrace the challenges posed by a rapidly evolving industrial landscape and remain committed to leading the way in providing quality, durable equipment solutions. By staying ahead of emerging trends, continuously listening to our customers, and innovating, we aim to contribute to a future where industrial progress harmonizes with environmental stewardship. Together, we aim to shape and play a significant role in creating a more sustainable tomorrow.

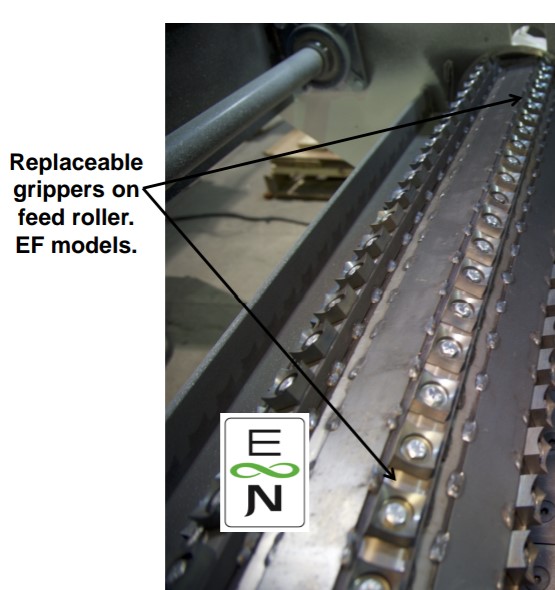

EVER-NEW Replaceable Grippers on EF Models Feed Roller

Our American made industrial shredders and grinders have been intentionally designed to faithfully serve their purpose for decades. There are elements of the machines that are exposed to a great deal of wear and tear. This of course includes the consumable items on the machine – the cutting teeth, screens, and stationary anvils. We produce and inventory our own tooling and screens, allowing us to carefully control their quality standards and ensure the ability to ship most of these items on the same day. Yet beyond these consumable items on the system, we have carefully studied how these machines can be reset to a “factory-new” condition, even after a devastating tramp metal incident or normal wear and tear resulting from years of daily rugged use. This is where our EVER-NEW Technology shines.

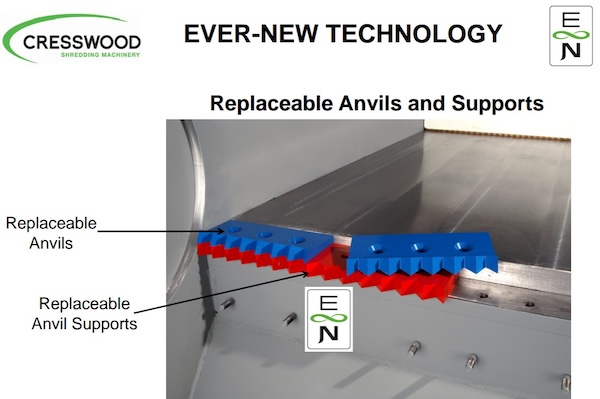

EVER-NEW Stationary Counter-Knives

The first key area where the technology is deployed is in the stationary anvils and the die support where they are mounted. A tramp metal incident will break or chip the teeth of the anvils and necessitate their replacement. The severity of the forces involved will also translate to damages to the underlying support. Cresswood, a world class industrial grinder and shredder manufacturer, designs our anvils in a modular fashion, meaning that if one specific section of the tooling is damaged, that particular section can be replaced leaving the sections in good condition intact. This promotes significant cost savings over having to replace the entire length of tooling. Another great feature is the presence of Cresswood’s replaceable anvil supports in the design. These modular plates absorb the impact forces and protect the underlying die support. They are relatively cheap and easy to remove and replace. The die support itself is a significant investment in the overall frame of the machine, and having to replace it is a major cost. It is also difficult to impossible to try to repair a severely damaged die support to new condition. For these reasons, this is a key area where our EVER-NEW technology has been deployed and contributes to lowering the cost of ownership of the machine over time.

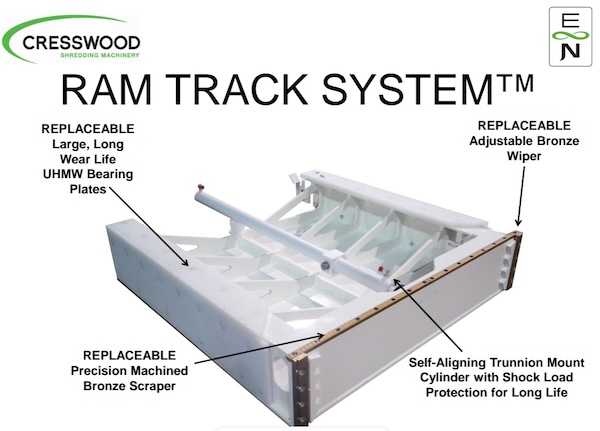

RAM TRACK SYSTEM

On a vertically-fed industrial grinder or shredder, the material is fed into the cutting rotor via a hydraulically driven ram. This ram will cycle hundreds of thousands of times over the course of years in service, so there is naturally a great deal of wear on the moving parts that are exposed to the surface of the machine’s frame. Cresswood’s EVER-NEW technology on the ram consists of UHMW bearing plates on the bottom and side surfaces of the ram. This material is naturally very slippery and wear-resistant and is made from a relatively softer material than the steel frame it rubs against. The front and side surfaces of the ram consist of bronze wipers. These create an easily adjustable tight seal with the side frame and underlying bedplate to prevent any material migration between or underneath. This helps eliminate any ram jamming, while the bronze material is relatively soft and won’t wear the frame of the machine, protecting the main investment. Cresswood produces all of these EVER-NEW components and keeps them in stock for same-day delivery.

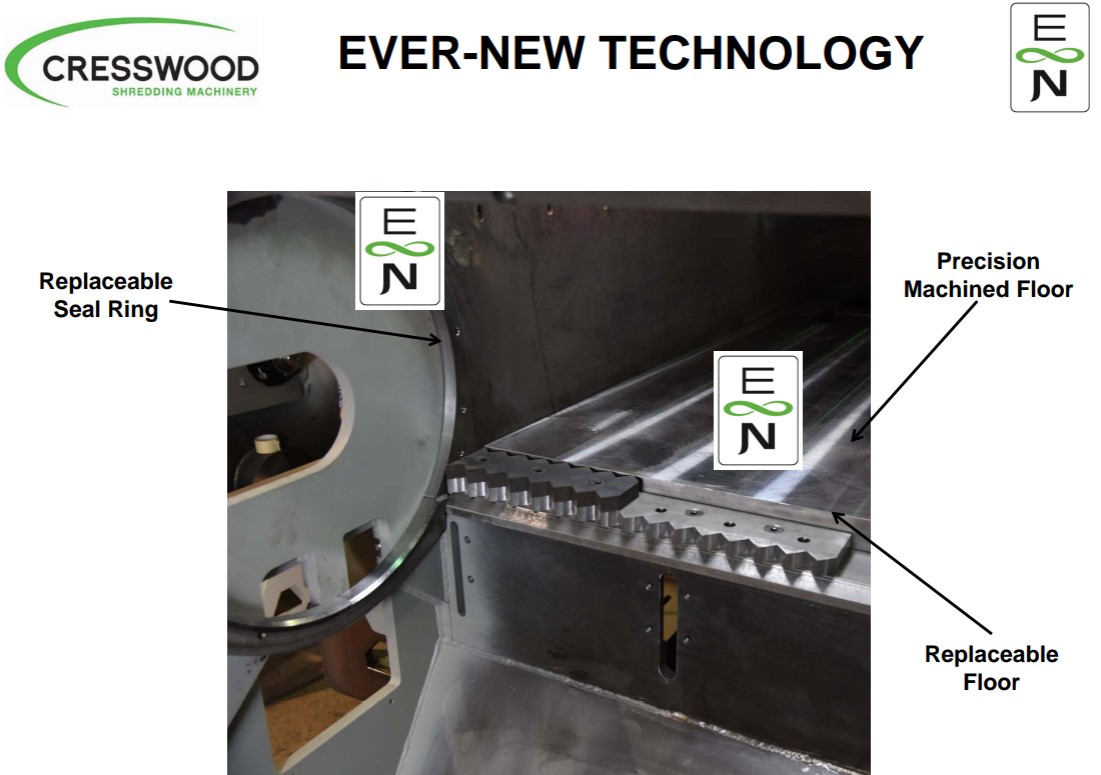

EVER-NEW Replaceable Seal Rings

EVER-NEW Bronze Ram Guides

The final key area where the Cresswood EVER-NEW technology is present is incorporated into the frame of the machine itself. The moving ram is kept in proper alignment with adjustable ram guides that are lined with a precision-machined bronze guide plate. The bronze material is once more used to protect the steel fabrication of the ram and is quickly and easily replaced once its useful life is spent. The seal rings on the outer portions of the rotating cutterhead mate with precision-machined seal rings attached to the side frames of the grinder itself. A tight seal is created that prevents material from migrating outside the cutting chamber. Over time the seal rings on the frame are worn to a point where the seal needs to be reset to factory-new tolerances. We have created individualized seal plates for the frame that are easily removed and bolted into place. Our machine shop produces these from raw materials, allowing us to tightly control quality and critical tolerances while maintaining rapid delivery of parts.

Each of these EVER-NEW features allow decades of smooth performance even in the toughest applications. The ability to reset the Industrial grinder or shredder to a “factory-new” condition makes the overall cost of ownership much more attractive over the long haul, long after that new grinder smell is gone!

Experience the pinnacle of American-made industrial shredder technology with Cresswood Shredding Machinery. Our cutting-edge equipment is revolutionizing industries, offering durability, efficiency, and sustainability. From the heaviest builds to precision engineering, our machines are engineered to withstand the most brutal operating conditions for years to come. Contact us to explore our range of used machine shredders and new ones to discover how Cresswood’s EVER-NEW Technology is innovating durability for a more sustainable tomorrow.

Recent Comments