When our American-made industrial shredders and grinders leave the warehouse, three dedicated team members play a crucial role in ensuring each machine meets the highest standards. They meticulously inspect and test the equipment, ensuring it operates at peak performance while also enhancing its appearance. This attention to detail guarantees that our shredders and grinders not only look their best but also reflect our commitment to quality craftsmanship. Additionally, these team members oversee the careful packaging and handling of the machinery, making sure it is securely loaded for transport. Their efforts ensure that our customers receive top-notch products that are ready for use, along with the peace of mind that comes from knowing their equipment has arrived safely and in perfect condition.

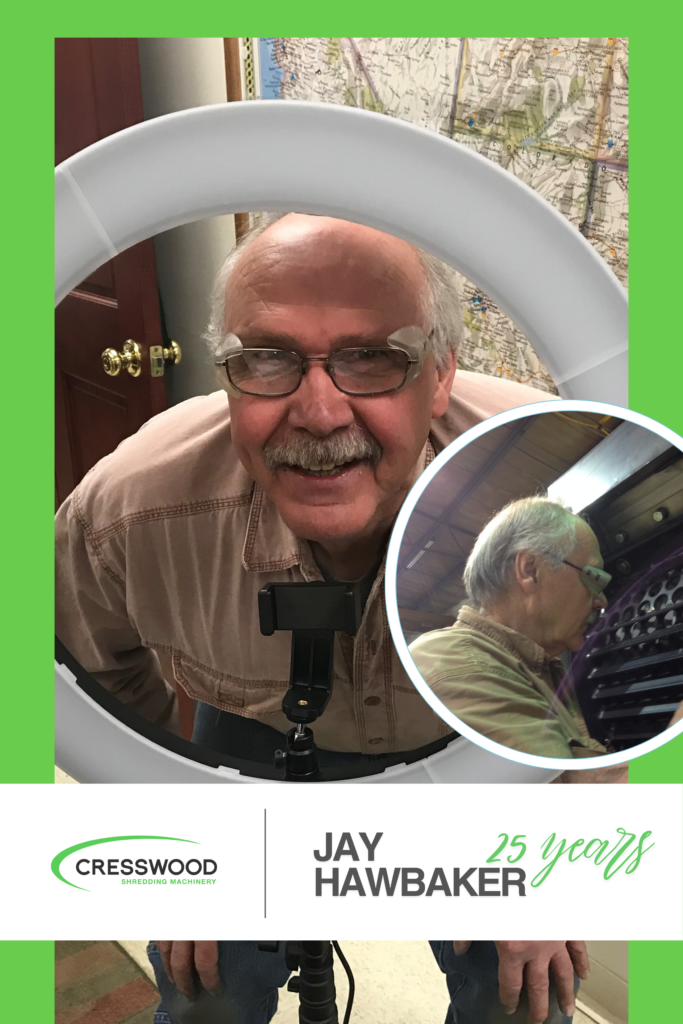

“In my 25 years here at Cresswood, I have seen many improvements not only in the design of our machines but also in our processes here in the shop. Because of these improvements, we can assemble the machines a lot more efficiently.” – Jay Hawbaker

Jay Hawbaker – 25 Years

Over the last 25 years, Jay has helped assemble hundreds of machines, taking them from a bunch of different parts located throughout the shop to one piece of working equipment. He starts the assembly process by filling a cart with all of the parts needed for each specific machine so that things stay clean and organized on the floor. Jay is the type of guy who will do anything or can assist with many different things, he’s our anything-and everything kind of guy.

Out in the shop he can be seen doing many of the following things on a pretty regular basis; installing screw augers, putting covers on the fronts of machines, moving materials on the shop floor after a test grind, or grabbing weights and dimensions for the shipping department.

Alejandro Martinez – 18 Years

Alejandro is almost like the middleman in the assembly department. Jay gets a lot of the pieces ready and Steve makes things look nice once they are all together. Alejandro takes care of the insides of the machine. He is always normally making sure that rams are in their correct place, he’s installing inserts onto cutterheads and making sure that screens with the correct perforation sizes are being situated into the guts of the machine properly. Alejandro’s welding experience is also essential when he welds torque arms onto our shredders.

Steve Randall – 12 Years

Have you ever seen one of our brand-new grinders? They are a perfect bright white adorned with a few different decals. Steve is the one who paints all of our machines. What you may not realize is that Steve isn’t just painting our machines – he’s also painting conveyor belts, hoppers, and covers, basically if it’s white; Steve painted it. Everything is painted so precisely because Steve meticulously tapes around anything that shouldn’t be painted before bringing the items into the paint booth. After the assembly team puts the last few pieces together, each machine then gets a thorough once over and gets touched up with paint in any place necessary. After the machines dry, Steve then shrink-wraps our machines so that they can be shipped safely without getting any scratches.

Recent Comments