As we close out 2024, it’s a perfect time to reflect on the year’s challenges, successes, and the evolving landscape of the industries we serve. From shifting economic conditions to technological innovations and new product developments, Cresswood Shredding Machinery, a family-owned American-made industrial shredder and grinder company, has navigated a turbulent year while laying the groundwork for an exciting 2025.

The Impact of Uncertainty on Capital Equipment Spending

2024 has been a year of uncertainty, marked by a particularly divisive and turbulent election. The effects on businesses have been significant, with many companies taking a cautious “wait and see” approach to capital equipment spending. When the future is unclear, it’s natural for businesses to delay large projects and wait for a clearer picture. Some essential projects moved forward, but many others that were still uncertain were postponed.

High interest rates have also played a key role in shaping business attitudes toward spending. With large capital equipment purchases often requiring financing, the rising cost of borrowing has made it more difficult for companies to justify investments, as the expected return on investment (ROI) becomes harder to achieve. Additionally, inflation and rising labor costs have further complicated budget planning, adding to the already uncertain economic climate.

At Cresswood, a world class industrial grinder and shredder company, we’ve been able to leverage this environment to our advantage. The main value proposition of our equipment lies in the labor savings it delivers through more efficient material handling. As companies across the nation seek ways to automate and reduce unnecessary labor, our shredders and grinders offer a solution. By deploying grinders at the source of waste, we help businesses reduce or even eliminate the labor spent on handling scrap materials. With a tightening labor market, finding and retaining skilled employees is becoming more challenging, making it even more critical for businesses to streamline operations and focus their workforce on value-added tasks.

One of the core principles of lean manufacturing and continuous improvement is the reduction of waste—anything that the customer isn’t paying for when they purchase your product. While some waste is inevitable, there are always opportunities to minimize it and make operations more profitable. Our application sales team excels at identifying these opportunities and recommending tailored solutions, even in cases where our equipment might not be the perfect fit.

Pallet Industry Woes

The pallet industry, one of our key markets, has faced particularly tough times in recent years. The boom in demand for recycled pallets during the pandemic was followed by a significant collapse in prices. Where pallet manufacturers were once struggling to meet demand, they now face a glut of oversupply, rising labor costs, and volatile lumber prices.

In fact, prices for Grade A GMA pallets have plummeted to a quarter of their peak during the pandemic, making it difficult for pallet manufacturers to stay afloat. This has led to an increased focus on recycled pallets, with some companies doubling down on pallet recycling efforts. The past 18 months have been brutal, with labor costs rising 30% from March 2020 to September 2023—well above the 18% increase seen across the general manufacturing sector.

For companies in the pallet recycling space, Cresswood’s industrial shredders are crucial tools for handling the growing demand for recycled materials. Our high-performance grinders and shredders provide fast, efficient size reduction, enabling pallet recyclers to process large volumes of waste while reducing the need for manual labor. In the face of these industry challenges, the ability to streamline operations and reduce costs is more important than ever.

Housing Crunch & Its Impact on Wood Recycling

The housing market has also faced significant challenges in 2024, with high mortgage rates and overall economic uncertainty cooling demand for new housing construction. Industries dependent on the housing market, such as cabinet makers, hardwood flooring suppliers, and millwork shops, have seen a decline in demand for raw materials.

Cresswood, which serves a wide range of industries including wood recycling, has felt the ripple effects of this downturn. As fewer new homes are being built, there is a decrease in the volume of wood waste that would traditionally be recycled. At the same time, pandemic-driven trends in home renovation have cooled, further contributing to the slowdown.

However, we remain optimistic that the housing market will eventually rebound, especially as interest rates are expected to decrease in the coming year. Once the market stabilizes, there will likely be a renewed demand for wood products and, by extension, wood waste recycling. Our industrial shredders and grinders, such as the XR620, are designed to efficiently process large volumes of wood waste, and we look forward to supporting the industry’s recovery.

Huge Opportunity in Plastic Recycling

As the world moves toward more sustainable practices, plastic recycling has become an increasingly important focus. This year, Cresswood Shredding Machinery had the privilege of exhibiting at the Pack Expo at the McCormick Center in Chicago. The event allowed us to connect with professionals from across the plastic packaging industry and showcase our world-class industrial shredders, such as the SRV360.

Plastic recycling is a huge growth area, and our team is committed to providing not just equipment, but complete solutions for our clients’ material challenges. This means pairing our shredders with other critical technologies, such as conveyors, granulators, hammermills, and air systems.

At the Pack Expo, we partnered with Compass Systems to demonstrate the versatility of our equipment, with live demonstrations of our hopper-fed SRV360 under power at their booth. We were also joined by Nathan Harris, a Subject Matter Expert (SME) in secondary processes for both wood and plastic materials, who shared his expertise on pelletizing and the importance of comprehensive recycling solutions. As the plastic recycling industry continues to grow, Cresswood is excited to help lead the charge with cutting-edge technology and innovative solutions.

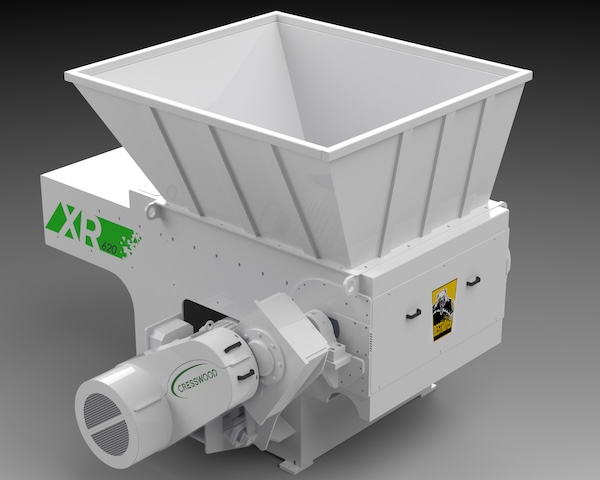

New Product Development: The XR620 Industrial Shredder

One of the major innovations we’re excited to unveil in 2025 is the new XR620 Industrial Shredder. This powerful machine has been redesigned to handle the toughest loads with increased rotor diameter and horsepower, making it ideal for recycling whole pallets and processing a variety of materials, including plastic film and paper.

The XR620 features a larger rotor diameter (from 16” to 20”) and offers 150hp and 200hp drive packages. The improved design boosts throughput by up to 30%, all while maintaining a compact footprint. Whether you’re dealing with wood waste, plastic, or other materials, the XR620 is designed to deliver maximum efficiency and performance, making it an ideal solution for pallet recyclers, plastic processors, and manufacturers across multiple industries.

We can’t wait to introduce the XR620 at upcoming pallet conferences in January and March of 2025.

Expanding Our Commitment to Community

In addition to our work in the industrial sector, Cresswood is committed to giving back to the community. As part of our social responsibility efforts, We plan to have an additional 6 raised garden beds for our spring planting next year. This 50% increase in our total garden space means that we will provide even greater support for the food insecure right here in our communities. One of the beds will be dedicated to my daughter Mayah who was taken from us in a tragic car crash this October. Wildflowers of all sorts will be planted and it will be a beautiful tribute to her life, and a way for her memory to live on and provide joy and beauty for others to enjoy for years to come.

Looking Ahead to 2025

As we look to 2025, we are optimistic about the opportunities ahead. While challenges remain, we believe that innovation, efficiency, and a commitment to quality will continue to drive our success and help our customers thrive. From the development of new products like the XR620 to expanding our reach in plastic and wood waste recycling, we are poised for a year of growth, innovation, and impact.

Thank you for your continued support. We look forward to partnering with you in the year ahead!

Recent Comments